FIRE TEST ON OUR TITAN DOOR - BS EN 1634-1

A fire-test, showing that our Titan doors comply with the new Europe-wide fire resistance standard BS EN 1634-1 (which replaces the previous British Standard for fire resistance)When you buy a Titan door, not only are you getting the state of the art in burglary prevention, but the door also serves as a fire-door.Our Titan Doors have been tested by an independent laboratory to the Europe-wide fire resistance standard BS EN 1634-1 (BS EN 1634-1 is designed to provide more realistic measurement of a product’s performance in the case of fire. ) and proved to meet the requirements for half-hour fire doors.

This standard replaces the previous British Standard for fire resistance testing, BS 476.

The Titan door is suitable for a wide variety of fire door applications in domestic and commercial buildings.

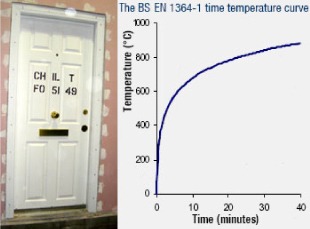

The sequence of images below shows a test being carried out on one of our Titan doors. Note that the door holds back flames for more than a full 30 minutes. This is being subjected to temperatures on the other side of the door, climbing rapidly to 600ºC, and in excess of 800ºC well before the 30-minute point!

The tests are designed to replicate the product’s intended end-use i.e. doors are built into an appropriate supporting construction. The specimen and any relevant supporting construction is built into a 3m x 3m restraint frame which is mounted on the front of a furnace.

The temperature within the furnace is controlled according to an internationally-accepted time/temperature regime, intended to simulate a post-flashover condition. Flashover is the point at which all objects in the fire compartment have ignited.

Testing is continued for the required duration – 30 minutes – or until the specimen fails and it is no longer safe to continue.

Failure relates to integrity, insulation and load-bearing capacity (if appropriate). Integrity failure is determined by 3 criteria:

Cotton pad – this shows that gases passing through the specimen are sufficiently hot to ignite combustible material on the non-fire side and therefore spread the fire

Gap gauges – these measures the width of gaps in the specimen and must remain below prescribed levels.

Continuous flaming – simply the fact that sustained flaming has occurred on the non-fire side.